|

|

| 100 to 999 |

| #100 ... #999 |

| ; | Following the ';' are ignored up to the newline character |

| (...) | Content within parentheses is ignored |

| = |

| > | More |

| < | Less |

| == | Equal |

| != | Not equal |

| >= | Greater than or equal to |

| <= | Less than or equal to |

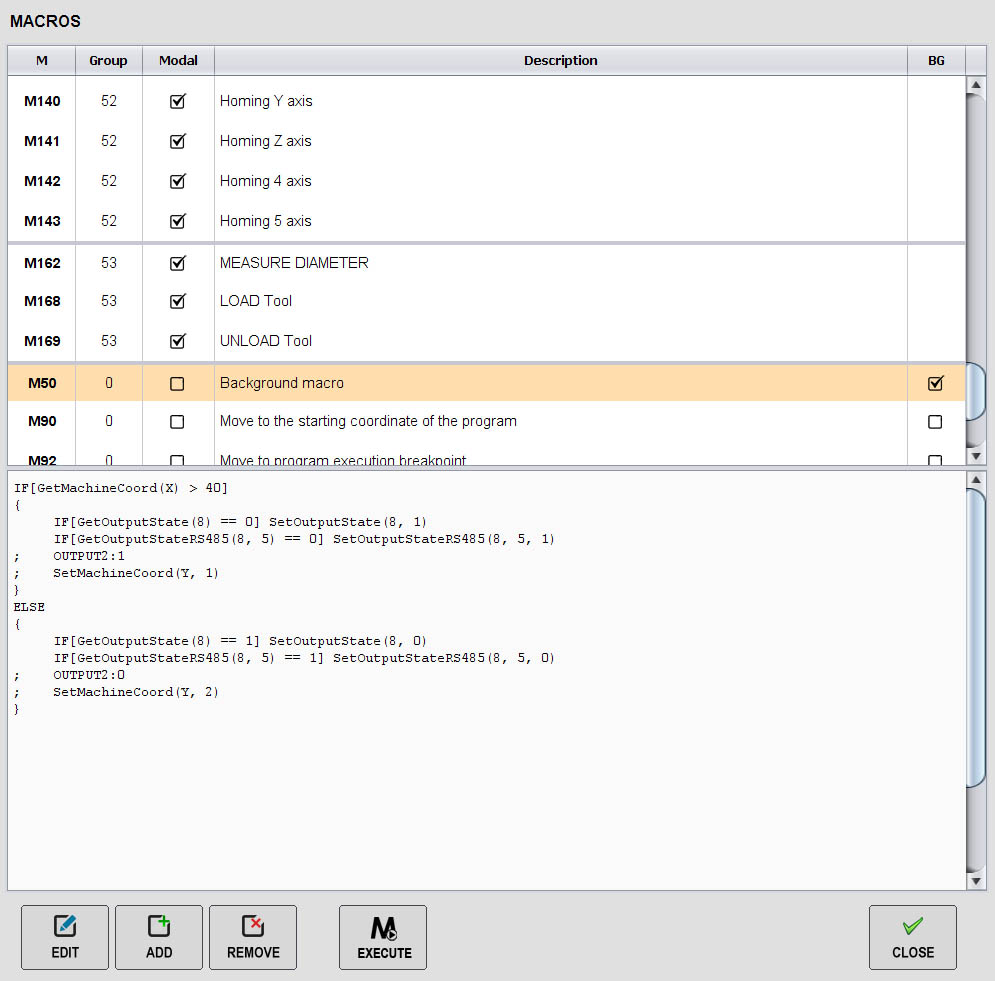

| IF[...] <...> | If [true/false], then <...> |

| IF[...] { <...> } ELSE { <...> } |

If [true/false], then { <...> }, else { <...> } |

| WHILE[...] { ... } |

As long as the expression in square brackets is true, execute the code in a loop. |

| #PARAM<P> | The value of the <P> parameter (for parameters of type Integer, Double, Boolean) |

| #X | The value of the current machine coordinate along the X axis |

| #Y | The value of the current machine coordinate along the Y axis |

| #Z | The value of the current machine coordinate along the Z axis |

| #A | The value of the current machine coordinate along the A axis |

| #B | The value of the current machine coordinate along the B axis |

| #C | The value of the current machine coordinate along the C axis |

| #ZPX<...> | Zero point value <...> along the X axis, where <...> -> 53...59, 5401...5499 |

| #ZPY<...> | Zero point value <...> along the Y axis, where <...> -> 53...59, 5401...5499 |

| #ZPZ<...> | Zero point value <...> along the Z axis, where <...> -> 53...59, 5401...5499 |

| #ZPA<...> | Zero point value <...> along the A axis, where <...> -> 53...59, 5401...5499 |

| #ZPB<...> | Zero point value <...> along the B axis, where <...> -> 53...59, 5401...5499 |

| #ZPC<...> | Zero point value <...> along the C axis, where <...> -> 53...59, 5401...5499 |

| MDI("<COMMAND>") | F | Executing an MDI command <COMMAND> |

| GetInputState(<N>) | F | Get the current state of digital input <N> (0-not active or 1-active; in case of an error, the value -1 is returned). |

| GetOutputState(<N>) | F | Get the current state of digital output <N> (0-not active or 1-active; in case of an error, the value -1 is returned). |

| SetOutputState(<N>, <0;1>) | F | Set digital output <N> to 0-inactive or 1-active state. |

| GetOutputStateRS485(<N>, <A>) | F | Receive from the external output block with address <A> the current state of the digital output <N> (0-not active or 1-active; in case of an error, the value -1 is returned). |

| SetOutputStateRS485(<N>, <A>, <0;1>) | F | In the external output block with address <A>, set the digital output <N> to 0-active or 1-active state. |

| GetMachineCoord(<C>) | F | Returns the current value of machine coordinate <C>. |

| GetProgramCoord(<C>) | F | Returns the current value of the program coordinate <C> from the loaded NC to the system. Possible arguments to <C>: X, Y, Z, A, B, C, U, V, W |

| GetWorkCoord(<C>, <WCS>) | F | Returns the current value of the <C> coordinate of the zero point <WCS>. Possible arguments to <C> are: X, Y, Z, A, B, C, U, V, W. <WCS> -> 53...59, 5401...5499 |

| SetMachineCoord(<C>, <V>) | F | Set the new value <V> of the machine coordinate <C>. |

| GetCurrentFeed() | F | Returns the current movement speed value. |

| GetProgramFeed() | F | Returns the value of the movement speed specified in the NC file. |

| GetOverrideFeed() | F | Returns the current value of the motion speed offset (in percent). |

| SetOverrideFeed( | F | Set a new value |

| SetSpindleRPM(<N>, <S>) | Set the rotation speed value <S> [rpm] for spindle <N>. | |

| StartSpindleCW(<N>) | Starts spindle rotation in the forward direction for spindle number <N> | |

| StartSpindleCCW(<N>) | Start spindle rotation in reverse direction for spindle number <N> | |

| StopSpindle(<N>) | Stop rotation for spindle number <N> | |

| WaitSpindleRPM(<N>) | Wait (do not continue executing the program) until the spindle speed <N> reaches the specified value | |

| GetActiveSpindle() | F | Returns the number of the currently active spindle: from 1 to 4 |

| GetSpindleERRORcode(<N>) | F | Returns the error code in the operation of the frequency converter for spindle number <N> |

| IsSpindleStopped(<N>) | F | Returns the status of spindle number <N>: STOPPED (or RUNNING) |

| GetCurrentSpindleRPM(<N>) | F | Returns the current spindle speed <N> [rpm]. |

| GetTargetSpindleRPM(<N>) | F | Returns the specified spindle speed value <N> [rpm]. |

| GetOverrideSpindle(<N>) | F | Returns the current value of the spindle speed override <N> (in percent). |

| Sleep(<T>) | F | Pause <T> milliseconds. Range 1 to 60000 milliseconds (up to 60 seconds) |

| Stop() | F | Simulation of pressing the STOP button |

| Start() | F | Simulation of pressing the START button |

| SetEnabledMIST(<B>) | F | Turning on/off the cutting fluid (coolant) by mist/spray. <B> - true or false. |

| SetEnabledFLOOD(<B>) | F | Turning on/off the cutting fluid (coolant) by watering. <B> - true or false. |

| GetPARAM(<P>) | F | Returns the value of the parameter with number <P> (for parameters of type Integer, Double, Boolean) |

| ShowMessage(<S>, <W>, <H>, <B>) | F | Displays the message <S> on the display screen. <W>,<H> - width and height of the panel. If <B> = 1, then the message blocks the panel; if <B> = 0, then the message does not block the panel. It is possible to use HTML tags in the message. |

| HomeAxis(<A>) | Search for machine zero along axis <A>. Possible arguments to <A>: X, Y, Z | |

| HomingComplete(<A>) | The search for machine zero along the <A> axis has been completed successfully. Possible arguments to <A>: X, Y, Z | |

| HomingReset(<A>) | The machine zero search for the <A> axis is not completed. Possible arguments to <A>: X, Y, Z | |

| SQRT(<N>) | F | Calculating the square root of a number <N> |

| #INPUT<N> | F | GetInputState(<N>) |

| #OUTPUT<N> | F | GetOutputState(<N>) |

| #OUTPUT<N>:A<A> | F | GetOutputStateRS485(<N>, <A>) |

| OUTPUT<N>:<0;1> | F | SetOutputState(<N>, <0;1>) |

| OUTPUT<N>:A<A>:<0;1> | F | SetOutputStateRS485(<N>, <A>, <0;1>) |