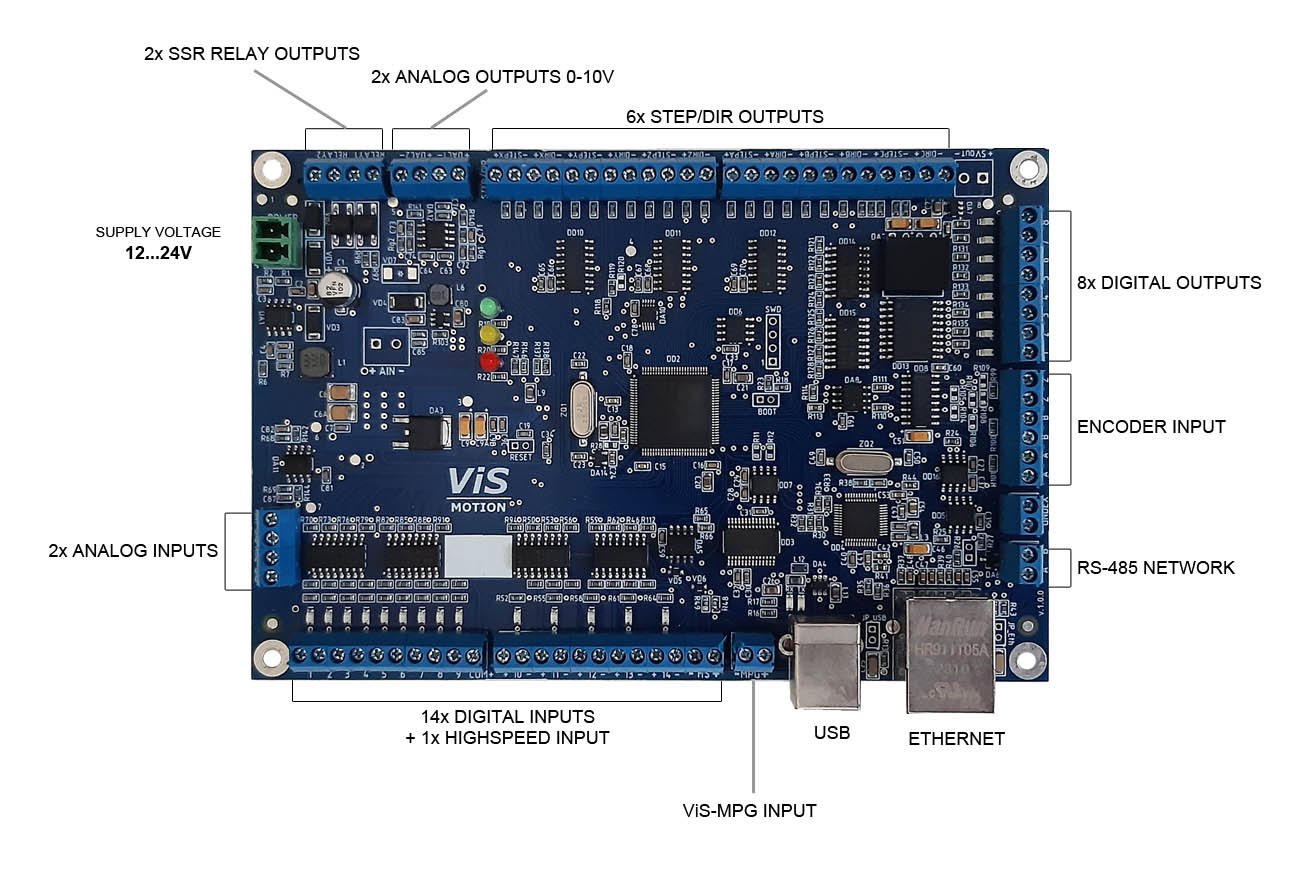

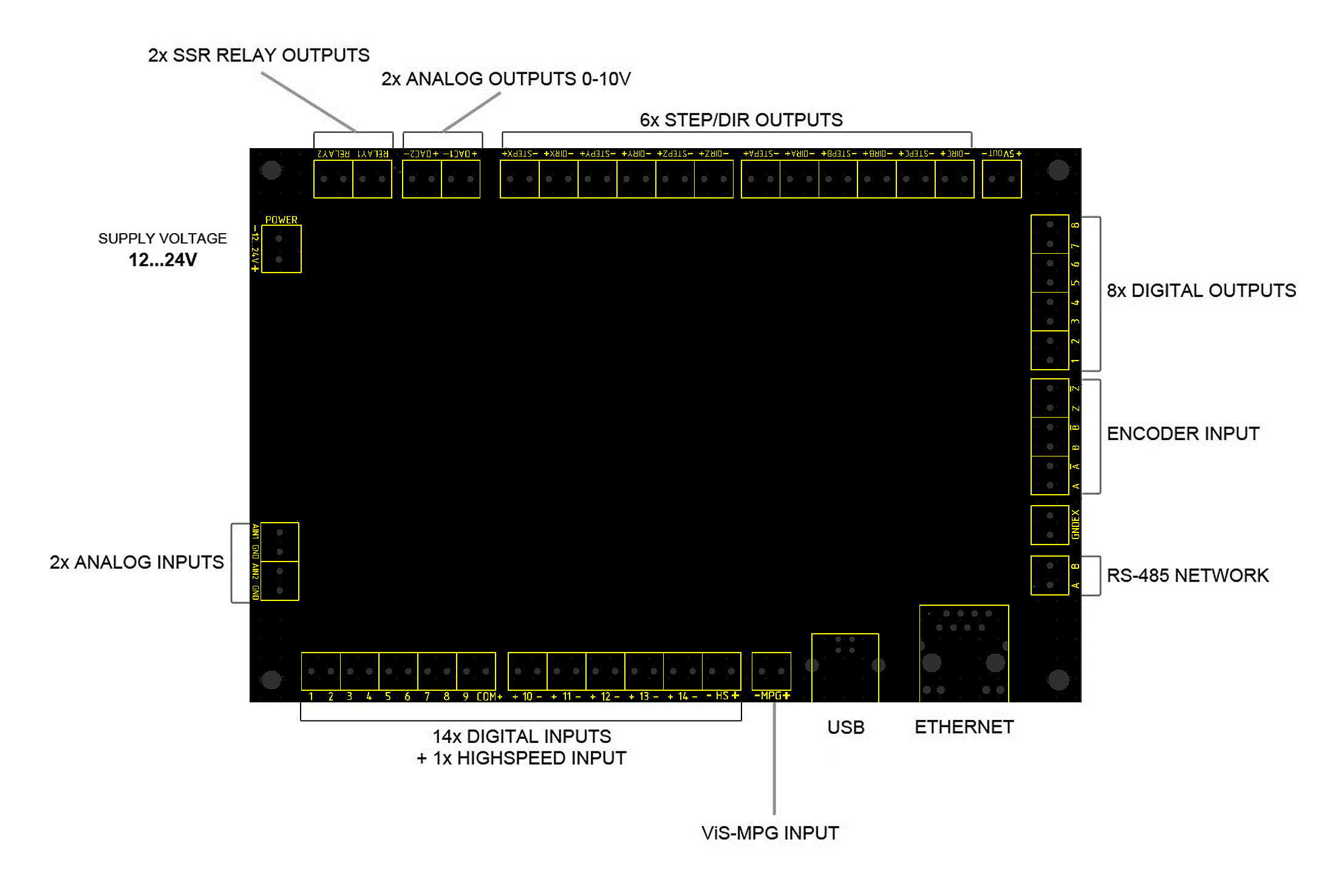

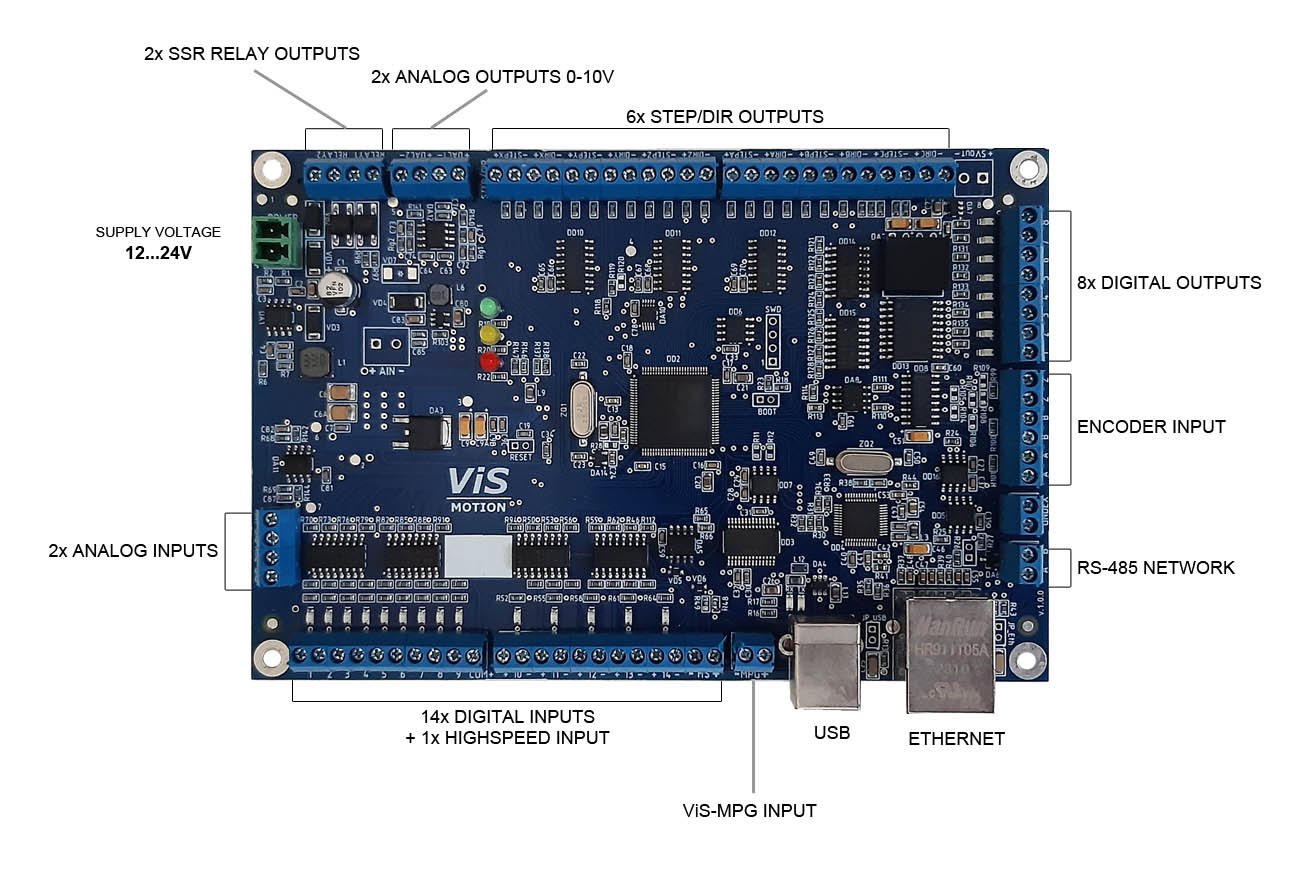

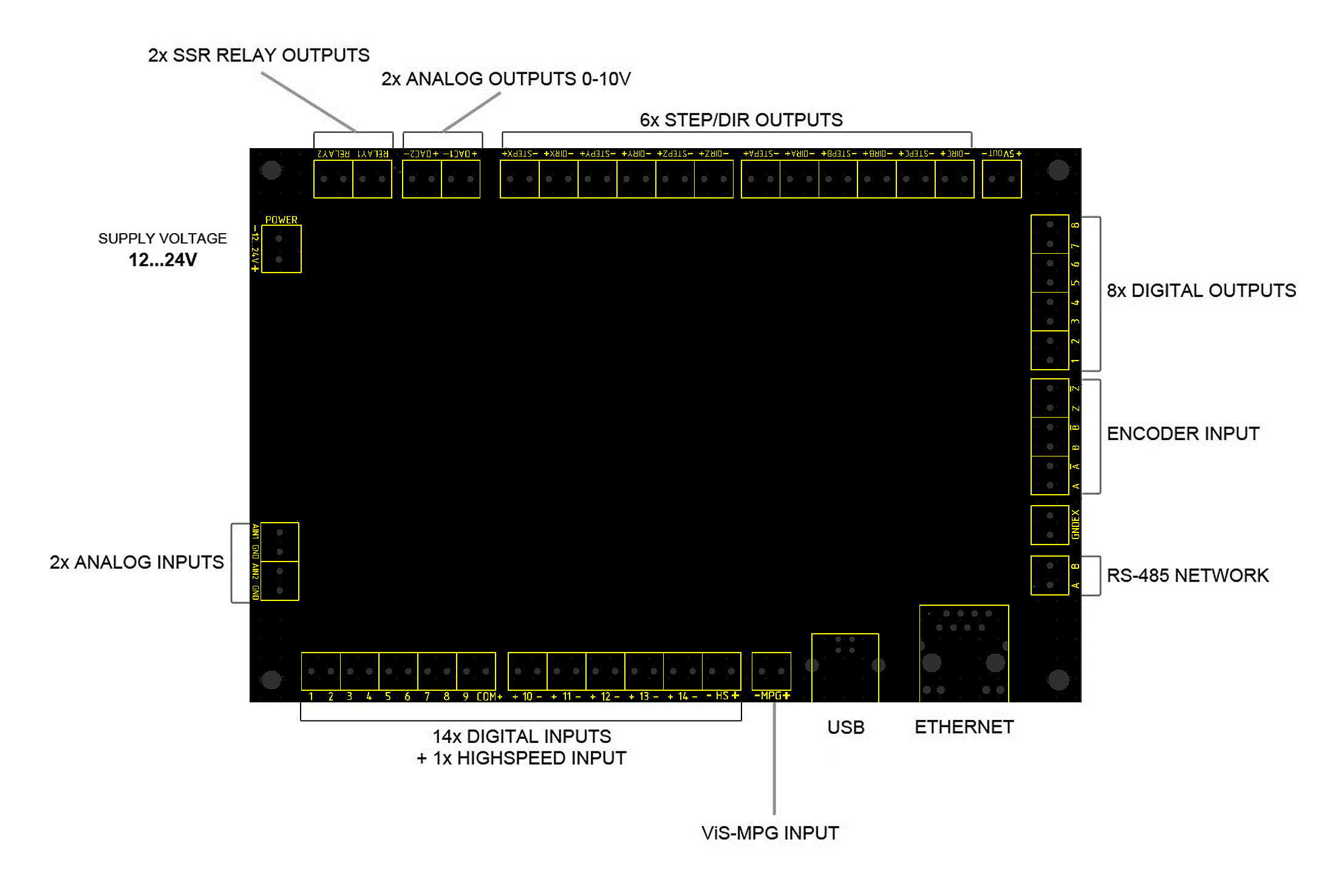

ViS-A3 / ViS-A4 controllers

ViS-A3 and ViS-A4 is a 6-axis motion controllers with 3 and 4 simultaneously interpolated axes respectively.

Compatible with almost all types of motors and can be used with both stepper and most brushless AC servo drives,

in fact any drive that is compatible with the STEP/DIR interface. Most stepper motor drives are compatible with the ViS CNC controllers (Leadshine, YAKO, ...).

The maximum number of inputs and outputs is not limited by the CNC controller itself. When the RS-485 network is included in the CNC system,

it is possible to increase the total number of inputs/outputs up to 240 (plus inputs/outputs on the CNC controller board).

USB

The USB interface can be used with the same functionality as the Ethernet.

The USB interface has complete galvanic isolation from the main controller circuit (high speed digital isolators are used).

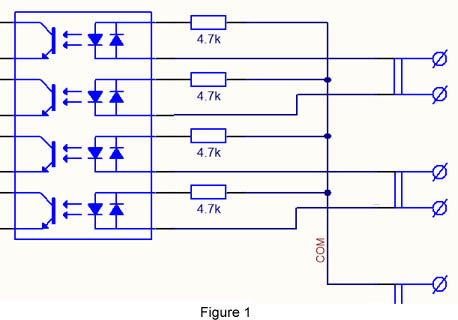

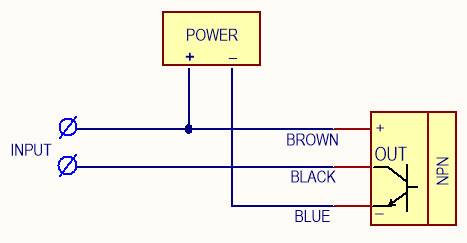

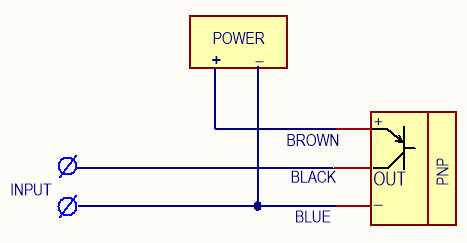

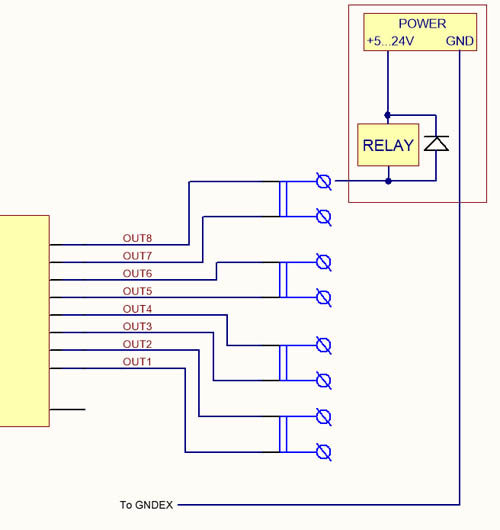

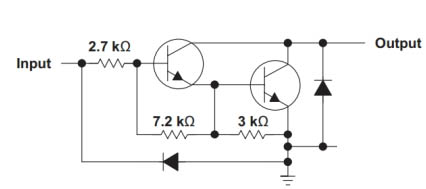

Digital outputs

ViS controller has 8 digital open collector outputs and 2 SSR relay outputs.

Each open collector digital output:

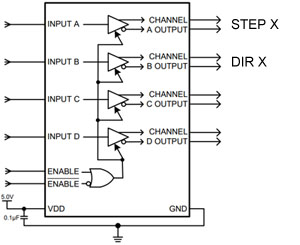

STEP/DIR outputs

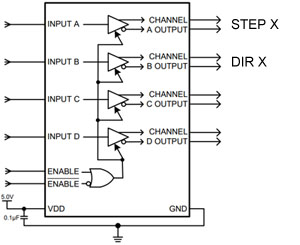

ViS-A3 and ViS-A4 has 6 STEP/DIR outputs.

But ViS-A3 has 3 simultaneously interpolated axes, ViS-A4 has 4 simultaneously interpolated axes.

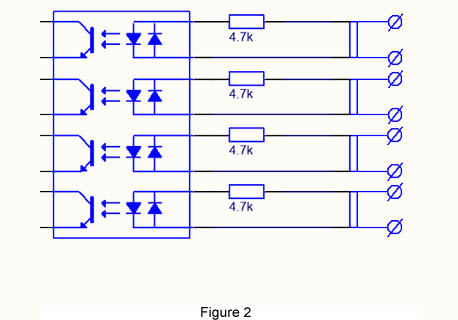

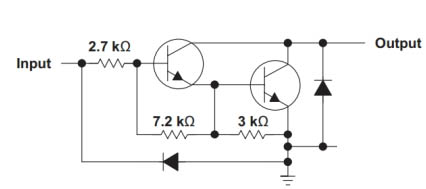

Each STEP/DIR output is a channel of inverting and non-inverting differential driver outputs,

which ensures error-free signal transmission over long distances even in noisy environments.

For stepper/servo drivers that do not support a differential input signal, we have developed a new module

ViS-DIFF.

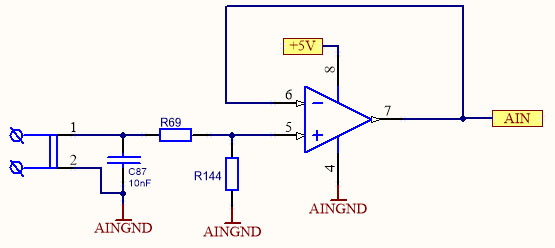

Analog outputs (0-10V)

ViS-A controllers has a 2 analog outputs 0-10V for spindle rotational speed control.

Maximum load of each analog output - 50 mA.

RS-485 interface network

ViS-A controllers has RS-485 bus for connecting devices that can operate using the Modbus protocol in the baudrate range from 9600 to 115200 bps.

All signals are galvanically isolated from the main controller circuit (high speed digital isolators are used).